We offer

Calculations

We provide calculations of the pressure equipment that are defected or in emergency condition due to short or long-term abnormal operation, environmental impact or due to design, structure, or technology defect. We solve defects of structures damaged by corrosion, corrosion cracking, fatigue, creep, abnormal deformations, abnormal settlement of subsoil and construction caused by defects of welding and fundamental material. At customer request we also add proposals for design and technology solutions required to keep the structures in operation.

Expert opinions

Strength analysis of systems, structures and components

Determining acceptability of defects found

Dynamic analysis of nuclear power plant equipment

Thermo-hydraulic analysis of nuclear power plant systems

Analysis and assessment of component degradation mechanism

Consultancy (for operators)

Determining the cause of damage to systems, structures and components

Regular assessment of component life (status)

Design and engineering activities for operators

Certificate documentation

Providing Certificates of Strength, durability and seismic resistance of nuclear power plant constructions and components

Optimalization of the Operational Control Program

Inspections of equipment in operation

Calculations of the strength, durability (fatigue), tightness of flange joints

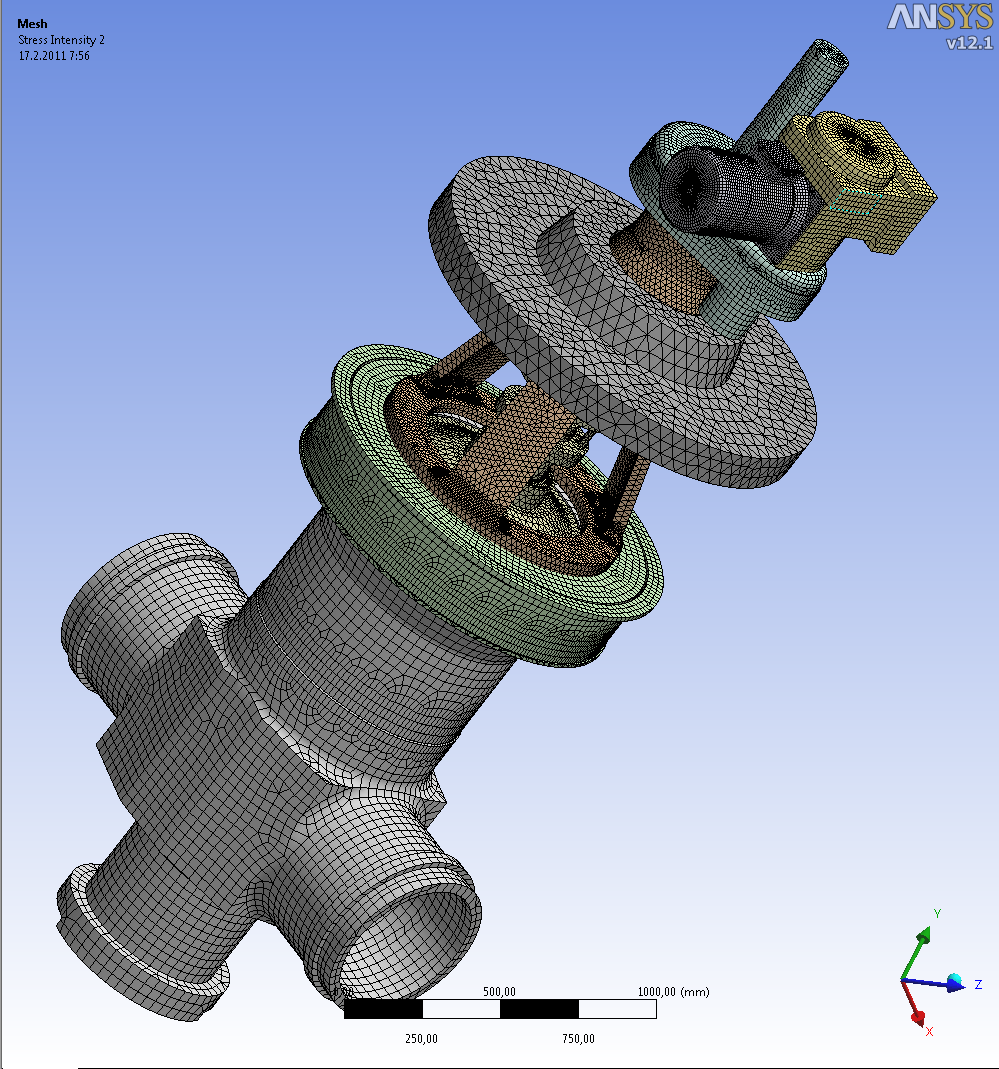

Models of drive fittings for static and seismic assessment

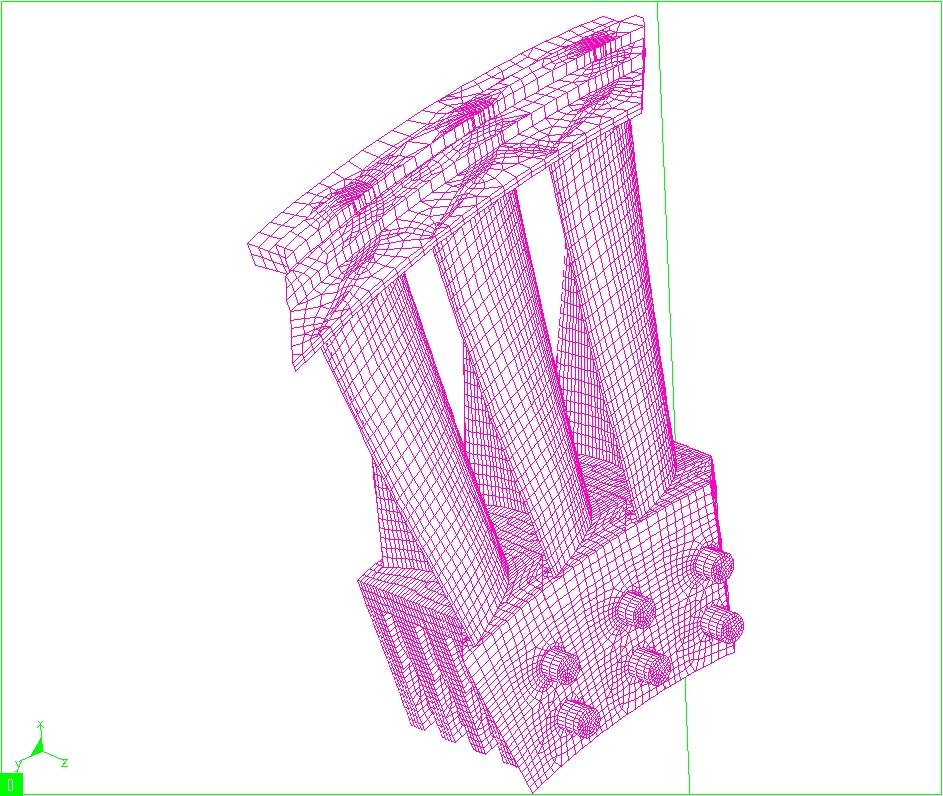

Models of turbine rotors for assessing effects on turbine blades mounting

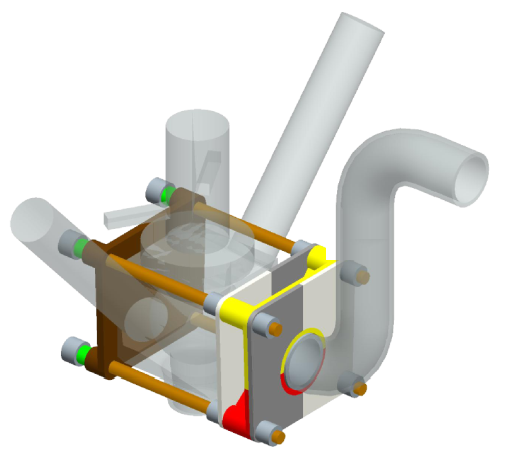

Verification models for pipe swing limiter design

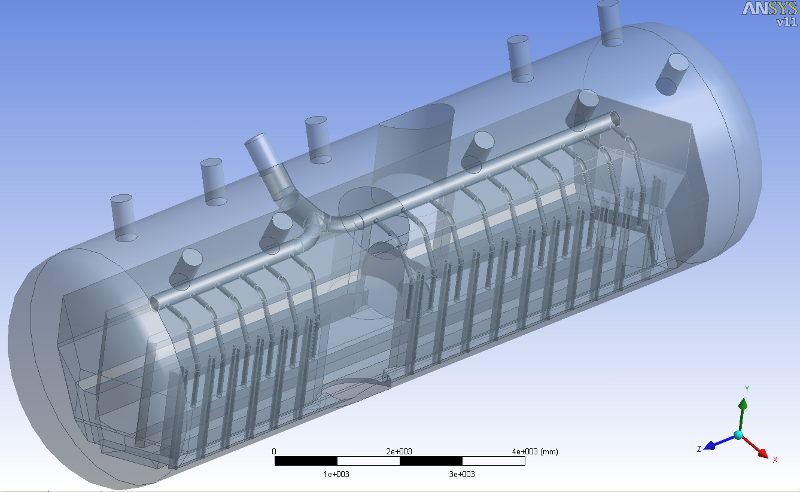

Models of feedwater supply for steam generators

Experimental measurements

Our laboratory provides experimental measurements at the customer’s to verify operational data (temperature, pressure, flow) and their impact on construction stress. We also provide static and cyclic tests of testing machines. In cooperation with the Computer Department we develop test procedures, equipment and preparations including their modifications or production. Our laboratory also provides verifications of computational models. There is the Accredited Test Laboratory 1228 as a part of our laboratory.

We offer

- Strain gauge measurement

- Temperature measurement

- Vibration measurement

- Fatigue tests

- Pressure measurement

- Light engineering production and modifications

- Design and develop equipment and devices for testing

Research and development of testing

In cooperation with the Computer Department of IAM we can design, develop, and produce test equipment and preparations within diverse requirements of our customers. These are mainly special clamping jigs to test on supplied samples. And there are also development and tune-up of testing procedures (i.e. measuring leakage rate of sealing joints).

Strain gauge measurement

Fatigue tests

Light engineering production and modificationsy

Development of equipment and devices for testing

References

- ČEZ a.s.

- Temelín NPP (nuclear power plant)

- Dukovany NPP

- Ledvice NPP

- Dětmarovice CPP (conventional power plant)

- Prunéřov CPP

- Počerady CPP

- Mělník II CPP

- Tušimice I and II CPP

- University of Mining Ostrava

Accredited laboratory

The Accredited Test Laboratory 1228 (ATL) is an independent entity within IAM Brno, Ltd. and it works closely with all IAM Brno specialists in meeting the demands of customers. Thanks to the growing cooperation with the IAM theory experts we can make very complex measurements in all technical fields.

We offer

- Residual stress measurement

- Strain gauge measurement

- Weight and Force measurement

- Static load tests

- Dynamic tests

- Long-term fatigue tests

- Destructive tests

- Surface temperature measurement

- Vibration measurement

- Pressure measurement

References

- Manufactures of construction machinery (AMMANN)

- Manufactures of track superstructure components